Views : 2937

QR code :

Time : 2024-05-21

AST160/200 Series automatic PV Cell String Layup & Bussing Machine

Introduction:

AST160/200 series automatic PV Cell String Layup & Bussing Machine is an automated equipment that combines the functions of PV

cell string layout and bus bar soldering, and is suitable for the production of small PV modules.

The PV Cell String Layup function is able to perform string pickup, positioning, layup, etc. and offers A/B string cutting feature.

The PV Cell bus bar soldering function uses a stable and reliable electromagnetic induction heating process to use a busbar to solder solar cell strings in series/parallel, thereby stably and efficiently meeting the production requirements of various photovoltaic module formats.

Product Features:

1. Offline/online dual mode: It can be connected with the soldering stringer machine for online feeding; it can also be combined with the material tray for offline feeding; or it can be used in dual modes in parallel. Dual mode parallel means that when the stringer is given priority to supply materials, if the stringer is too late to supply materials, it will automatically switch to the material tray to supply materials.

2. It can complete the layout and confluence of the PV cell strings of the intermediate outlet PV module, achieve dual parallel output of smaller power PV module, and obtain more stable and efficient products.

3. It can complete the shaping and positioning of two PV cell strings at one time and complete the PV cell string layout and soldering work of two PV modules with a length <=700mm at the same time.

4. The double-layer flip design enables one machine to achieve layup and confluence functions at the same time, and the two functions can be performed at the same time, it highly improved production efficiency.

5. Compatible with the soldering of 158.75/166/182/210 and other specifications of PV cell strings.

6. Suitable for the production of semi-flexible solar module and glass solar module at the same time. The two forms can be switched with one click.

7. Convenient specification conversion;

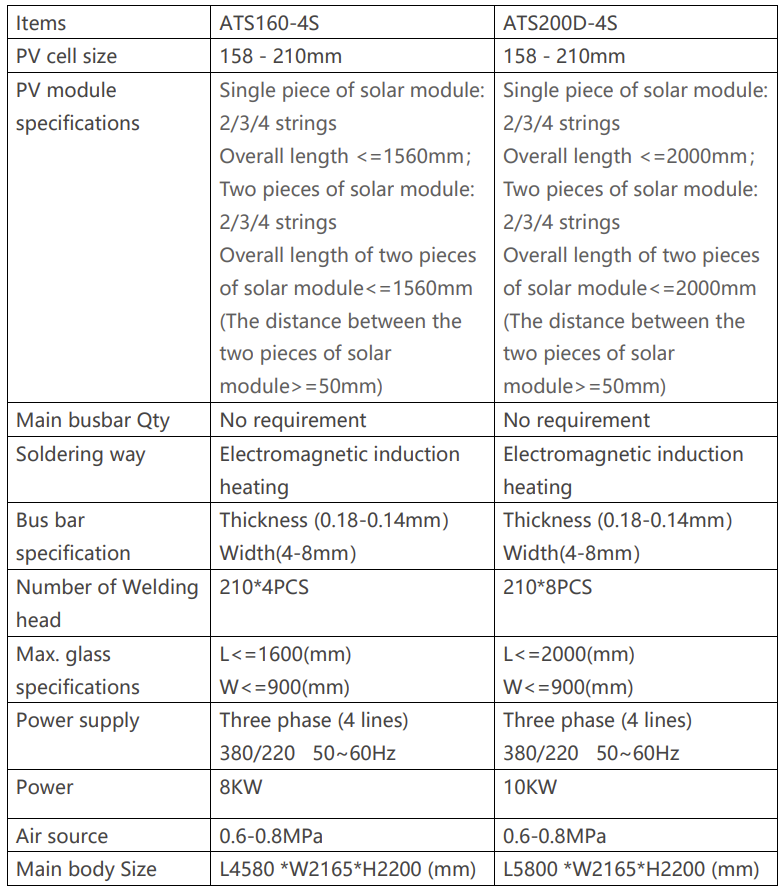

Products parameters: